REQUEST A QUOTE

Complete our quote form and we’ll get back to you promptly.

SERVICES

Vibratory Deburring

Fabricated metal and plastic parts frequently have rough edges or protrusions created during the manufacturing process. Our various methods of deburring remove these rough spots and create smooth, finished edges to customer specifications.

Pre-Plate Finishing

Defects in the product surface are magnified after plating. The pre-plate finishing process removes these defects prior to plating.

Shot Blasting

The Mannard Co. operates a 24 cubic foot tumble blast machine to process larger lots for faster turnarounds, and a 6 cubic foot machine for smaller batches.

Shot Peening

By blasting a product with small shot, peening creates small “craters” in the product surface. These craters create a desireable surface finish while strenghthening the material on a structural level.

Ball Burnishing

Burnishing is a cold finishing process where metal is abraded to reduce surface variation. It is less-costly than grinding or honing, and improves finish, hardness, and wear-resistance.

Parts Washing

We clean and remove all grease and debris from your parts. We can air dry parts or dry with granulated corn cob, an excellent absorbent. We are also a distributor for granulated corn cob products.

INDUSTRIES SERVED

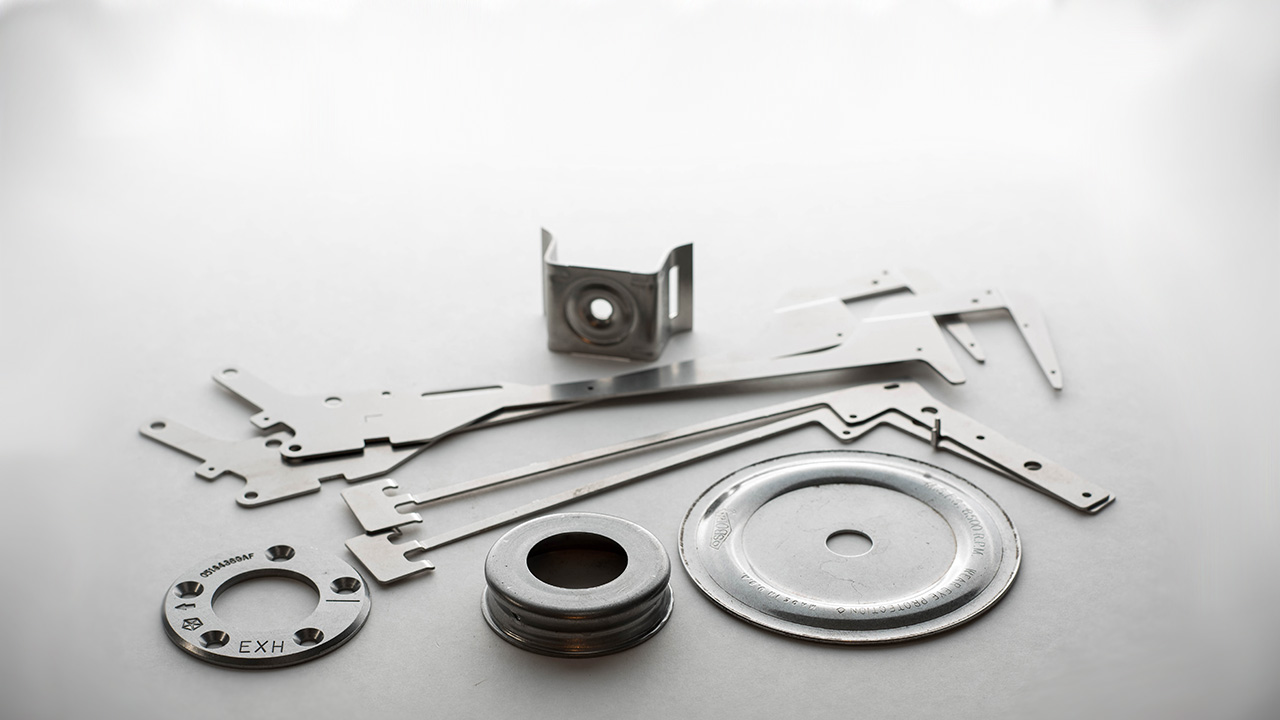

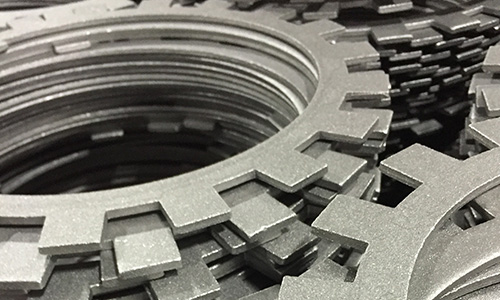

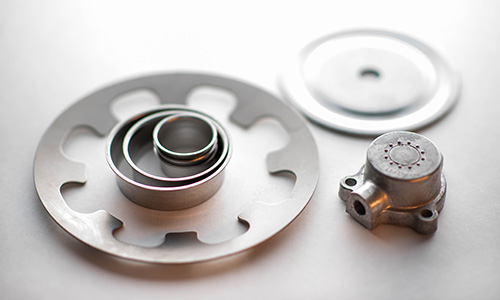

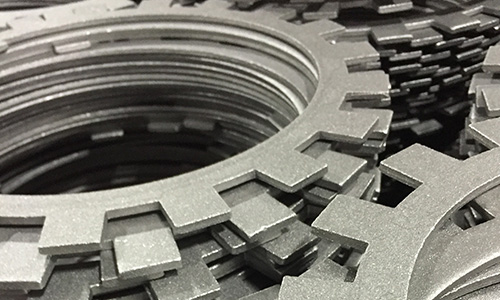

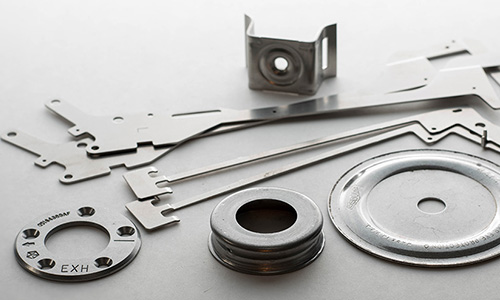

Stamping

Casting

Formed Parts

ABOUT US

OUR HISTORY

The Maynard Company was established in 1979 by Bud Maynard. Bud had been in the plating business his entire life when, at the age of 59 and with just 2 employees, he started The Maynard Co. At that time, they only did copper plating with Ford being their only customer

The Maynard Co. went through several transitions in business from plating to deburring rocker arms. Bud’s sons John and Tom Maynard took over the business in April of 1990 and with lots of hard work and dedication they expanded the business to include other parts. At that time, they were shot peening rocker arms at a rate of 1.2 million per month with just two tumble blast units and three vibratory machines.

TODAY

The Maynard Co. is now run by President and CEO John Maynard. The company sits in an 18,000 square foot facility in Brook Park, with 12 vibratory machines, one small blast unit and one extra large. When asked what keeps the company going, his response is very simple: It’s about the customers, family and tradition. He loves the people he works with and those who work for him. Building relationships is what it’s all about.

“ The Maynard Company has provided us with outstanding service from day one. We can’t recommend their services enough. ”